Many types of machines are used in metal processing industries to complete the work efficiently and to produce more in less time. A decoiler machine is also one such machine used in metal processing coil handling industries to unwind metal sheets. This machine is composed of various types of mechanical components. In this blog, we will explain you to about the decoiler machine, their functions, and the leading decoiler machine manufacturer in India.

Decoiler Machine

Decoiler machines play an important role in industries like sheet metal processing, coil handling, and roll forming. This is work to hold and unwind large metal coils, feeding them into machines for further processing. While its operation may look simple, a decoiler is made up of several key parts that work together to ensure smooth, safe, and efficient performance. Understanding these components can help in proper maintenance, troubleshooting, and maximizing machine life.

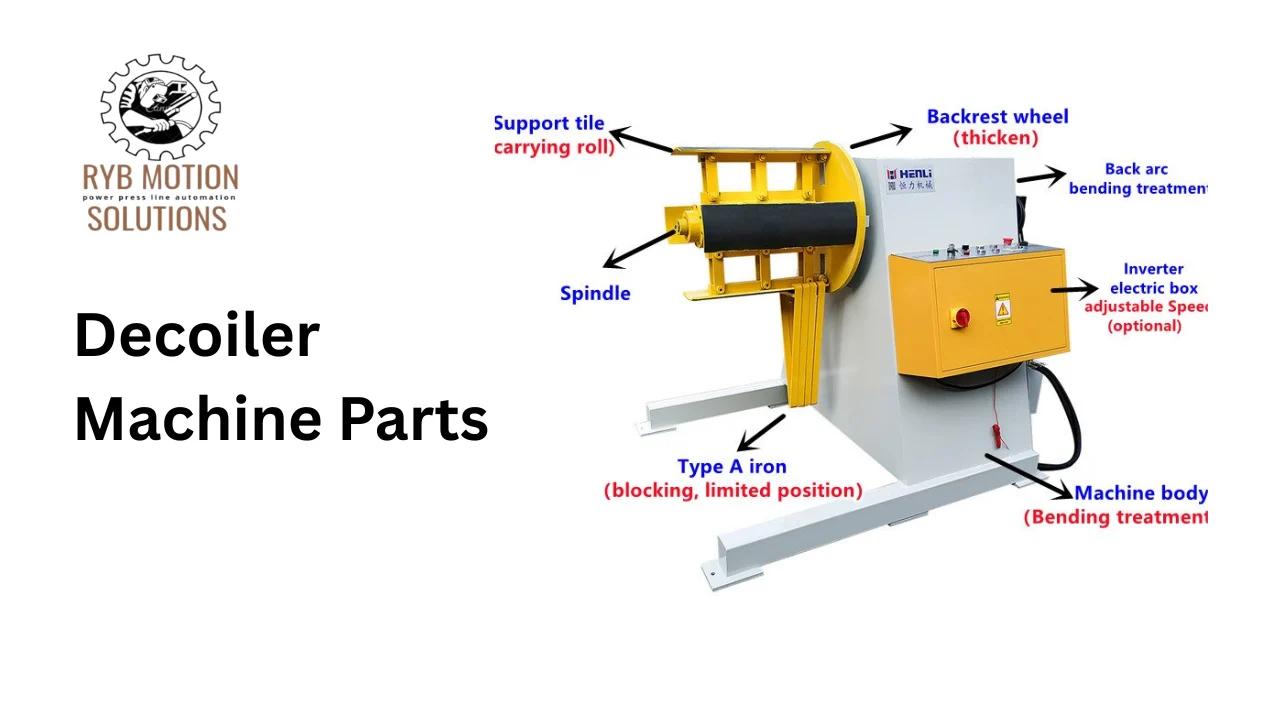

Decoiler Parts

- Mandrel / Spindle: The mandrel is the central shaft that holds the coil in place. It expands or contracts to grip the coil securely, preventing slippage during unwinding. In motorized models, it rotates to unwind the sheet at controlled speeds.

- Frame / Base: This is the sturdy structure that supports the entire decoiler. Built from heavy-duty steel, the frame ensures stability, especially when handling large and heavy coils

- Expansion Mechanism: Operated manually, hydraulically, or pneumatically, this system allows the mandrel to adjust according to coil inner diameter for a perfect fit.

- Brake System: The brake prevents the coil from over-spinning, ensuring smooth feeding and avoiding material wastage. It can be mechanical, pneumatic, or electromagnetic depending on the model

- Drive Motor (for Motorized Decoilers): In powered decoilers, the drive motor controls the rotation of the mandrel, providing consistent speed and tension during unwinding.

- Control Panel: This is the machine’s command center, allowing operators to adjust speed, tension, and expansion. Advanced panels may include touchscreens and automation settings.

- Coil Support Arms / Side Plates: These components keep the coil in position on the mandrel, preventing sideways movement during operation.

- Hydraulic / Pneumatic Unit (if applicable): For automatic expansion and control, some decoilers are equipped with hydraulic or pneumatic systems for quick and effortless operation.

- Safety Guards: Protective covers and guards ensure operator safety by preventing accidental contact with moving parts.

Importance of Knowing Decoiler Machine Parts

Familiarity with each part of a decoiler machine helps in:

- Quick troubleshooting during breakdowns.

- Better preventive maintenance.

- Ensuring safety and reducing downtime.

- Choosing the right spare parts when replacements are needed.

Uses of Decolier Machine Parts:

Decoiler machines are widely used in various industries where sheet metal or coiled materials need to be processed. Their main purpose is to hold, unroll, and feed material into different machines for further operations. Common uses include:

- Sheet Metal Processing – Feeding sheets into shearing, slitting, or stamping machines.

- Roll Forming Lines – Supplying continuous coil material to roll forming machines for making panels, channels, and profiles.

- Automotive Manufacturing – Unwinding steel or aluminum coils for body parts, chassis components, and panels.

- Pipe and Tube Mills – Feeding strip material into tube-forming and welding lines.

- Cut-to-Length Lines – Supplying coil sheets to machines that cut them into required lengths.

- Electrical Industry – Uncoiling copper or aluminum for transformer and motor manufacturing.

- Packaging Industry – Handling coiled materials like metal straps or foils.

RYB Motion Solution is a leading Decoiler Machine Manufacturer. We have the best knowledge about the decoiler machine parts are used in manufacturing our decoiler machine. We use good-quality deoiler machine parts in our decoiler machine so that our machine performs efficiently in our application. Regular inspection, cleaning, and lubrication of these components can ensure your decoiler operates efficiently for years. Whether you’re in sheet metal manufacturing, automotive, or fabrication, understanding your decoiler’s parts is the first step toward optimal production performance.