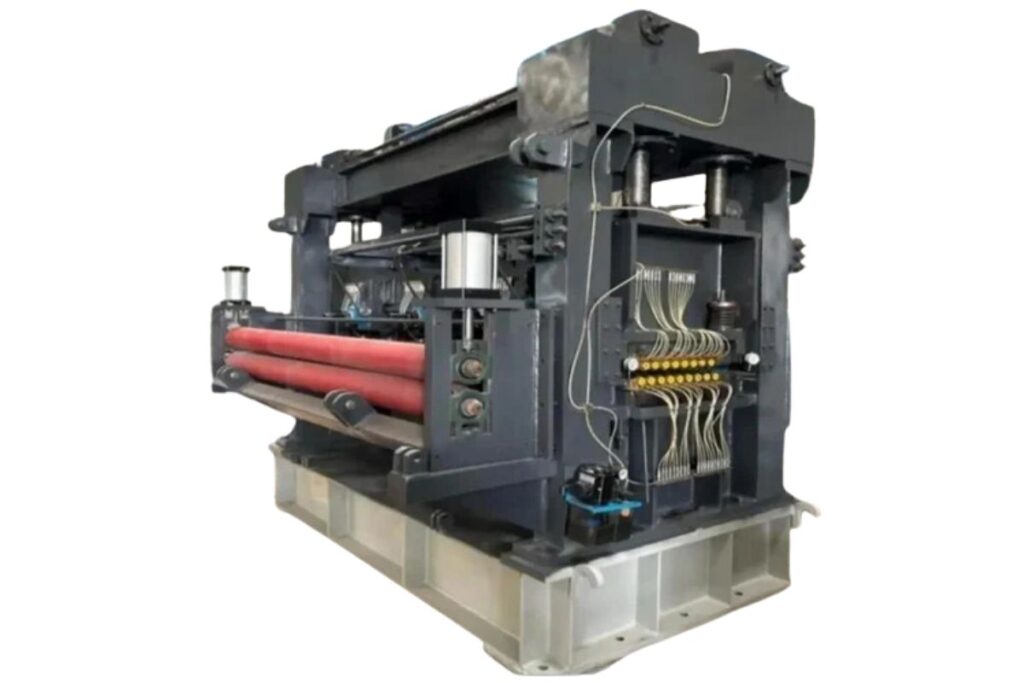

Sheet Leveler Machine Manufacturers

A sheet leveler is an industrial machine, which is mainly used in metalworking industries to flatten and correct sheet metal. Ryb Motion Solution is a leading Sheet Leveler Machine manufacturer. These machines are designed to remove internal stresses, waviness, and surface imperfections from metal sheets, ensuring uniform thickness and flatness. This sheet leveler machine sets the metal sheet one by one through a series of precision rollers arranged in an alternating pattern. Its robust construction guarantees durability and stability, making it ideal for demanding manufacturing environments.

Features of Sheet Leveler Machine

Our advanced models come with automatic adjustment features, hydraulic systems, and digital control panels for greater accuracy and efficiency. We offer various sheet leveler machines based on sheet width, thickness, and material type, sheet levelers can be customized to meet specific industrial needs. Their robust construction, high-speed operation, and precision performance make them a vital part of modern metal processing and fabrication lines. There are some specialized features of Sheet leveler machines, which make an impactful impression as a best sheet leveler machine manufacturer.

- Precision rollers for flat, stress-free sheets

- Adjustable settings for different materials and thicknesses

- Hydraulic or servo control for smooth operation

- Automatic thickness and alignment detection

- Durable, heavy-duty frame

- Easy-to-use touchscreen controls

As a leading Sheet Leveler Machine Manufacturer, we always focused on our product quality standards, reliability and durability and prioritized our customer needs. We provide these machines to a wide range of industries, including automotive, construction, appliances, and heavy machinery, where precision and surface quality are critical. With a focus on innovation and compliance with international safety and quality standards (like ISO and CE), we continuously invest in R&D to improve machine functionality and reduce operational downtime